Before you throw out the old brake pads or order a new set, take a good look at them. Worn brake pads can tell you a lot about the entire brake system and prevent the new pads from suffering the same fate. It can also help you to recommend a brake repair that returns the vehicle to like-new condition.

Rules Of Inspection

●Never judge the condition of the brake pads using just one pad. Both pads and their thicknesses need to be inspected and documented.

●Never take rust or corrosion lightly. Corrosion on the caliper and pads is an indication the coating, plating or paint has failed and needs to be addressed. Corrosion can migrate to the area between the friction material and backing plate.

●Some brake pad manufacturers bond the friction material to the backing plate with adhesives. Delamination can occur when the corrosion gets between the adhesive and friction material. At best, it can cause a noise problem; at worst, the corrosion can cause the friction material to separate and reduce the effective area of the brake pad.

●Never ignore the guide pins, boots or slides. It is rare to find a caliper that has worn out the brake pads without wear or degradation also taking place on the guide pins or slides. As a rule, when the pads are replaced so should the hardware.

●Never estimate life or thickness using percentages. It is impossible to predict the life left in a brake pad with a percentage. While most consumers might be able to understand a percentage, it is misleading and often inaccurate. In order to accurately estimate the percentage of material worn on a brake pad, you would first have to know how much friction material was present when the pad was new.

Every vehicle has a “minimum wear specification” for the brake pads, a number typically between two and three millimeters.

Normal Wear

No matter the caliper design or vehicle, the desired outcome is to have both brake pads and both calipers on an axle wear at the same rate.

If the pads have worn evenly, it is proof that pads, calipers and hardware have functioned properly. However, it’s not a guarantee that they will operate the same way for the next set of pads. Always renew the hardware and service the guide pins.

Outer Pad Wear

Conditions that cause the outer brake pad to wear at a higher rate than the inner pads are rare. This is why wear sensors are rarely put on the outer pad. Increased wear is typically caused by the outer pad continuing to ride on the rotor after the caliper piston retracts. This could be caused by sticky guide pins or slides. If the brake caliper is an opposed piston design, outer brake pad wear is an indication the outer pistons have seized.

INNER PAD WEAR

Inboard brake pad wear is the most common brake pad wear pattern. On a floating caliper brake system, it is normal for the inner to wear faster than the outer – but this difference should only be 2-3 mm.

More rapid inner pad wear can be caused by a seized caliper guide pin or slides. When this occurs, the piston is not floating, and equalizing force between the pads and the inner pad is doing all of the work.

Inner pad wear can also occur when the caliper piston is not returning to the rest position due to a worn seal, damage or corrosion. It can also be caused by a problem with the master cylinder.

To correct this kind of wear, take the same steps as fixing outer pad wear as well as inspect the hydraulic brake system and caliper for residual pressure and guide pin hole or piston boot for damage, respectively. If the pin holes or piston boot are corroded or damaged, they should be replaced.

Tapered Pad Wear

If the brake pad is shaped like a wedge or is tapered, it is a sign the caliper might have too much movement or one side of the pad is seized in the bracket. For some calipers and vehicles, tapered wear is normal. In these cases, the manufacturer will have specifications for the tapered wear.

This kind of wear may be caused by improper pad installation, but the more likely culprit is worn guide pin bushings. Also, corrosion under the abuttment clip can cause one ear of not move.

The only way to correct for tapered wear is to make sure the hardware and caliper can apply the pads with equal force. Hardware kits are available to replace the bushings.

Cracking, Glazing Or Lifted Edges On The Pads

There are multiple reasons why brake pads can overheat. The surface may be shiny and even have cracks, but the damage to the friction material goes deeper.

When a brake pad exceeds expected temperature ranges, the resins and raw components can break down. This can change the coefficient of friction or even damage the chemical makeup and cohesion of the brake pad. If the friction material is bonded to the backing plate using only adhesive, the bond can be broken.

It does not take driving down a mountain to overheat the brakes. Often, it is a seized caliper or a stuck parking brake that causes a pad to be toasted. In some cases, it is the fault of a low-quality friction material that was not adequately engineered for the application.

Mechanical attachment of the friction material can provide an extra layer of safety. The mechanical attachment goes into the last 2 mm to 4 mm of the friction material. Not only does mechanical attachment improve shear strength, but it also gives a layer of material that remains if the friction material will not separate under extreme conditions.

Defects

A backing plate can be bent as the result of any of several conditions.

●The brake pad can become seized in the caliper bracket or slides due to corrosion. When the piston presses on the back of the pad, the force is not equal across the metal backing plate.

●The friction material can become separated from the backing plate and change the relationship between the rotor, backing plate and caliper piston. If the caliper is a two-piston floating design, the pad can become bent and eventually cause a hydraulic failure. The main culprit of friction material separation is typically corrosion.

●If a replacement brake pad uses a low-quality backing plate that is thinner than the original, it can bend and cause the friction material to separate from the backing plate.

Corrosion

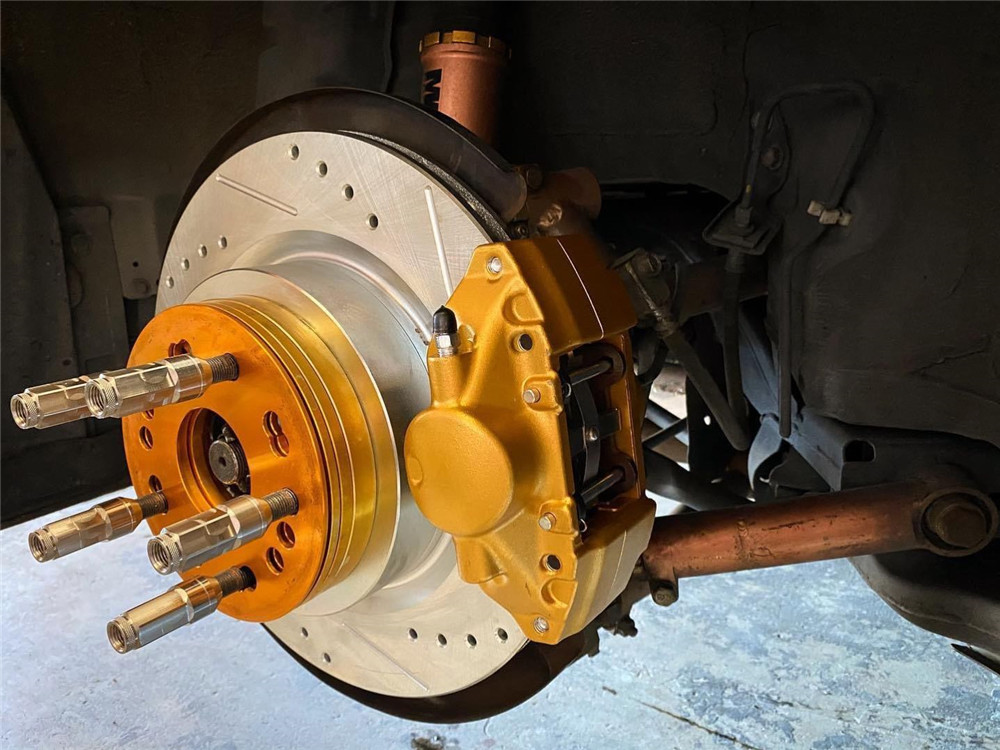

As stated before, corrosion of the caliper and pads is not normal. OEMs spend a lot money on surface treatments to prevent rust. Over the past 20 years, OEMs have started to use plating and coatings to prevent corrosion on calipers, pads and even rotors. Why? Part of the issue is to prevent customers from seeing a rusty caliper and pads through a standard alloy wheel and not a stamped steel wheel. But, the main reason for fighting corrosion is to prevent noise complaints and extend the longevity of the brake components.

If a replacement pad, caliper or even the hardware does not have the same level of corrosion prevention, the replacement interval becomes a lot shorter due to uneven pad wear or even worse.

Some OEMs use a galvanized plating on the backing plate to prevent corrosion. Unlike paint, this plating protects the interface between the backing plate and friction material.

But, for the two components to stay together, mechanical attachment is required.

Corrosion on the backing plate can cause delamination and even cause the ears to seize in the caliper bracket.

Tips And Guidelines

When it comes time to order the replacement brake pads, do your research. Since brake pads are the third most replaced item on a vehicle, there are many companies and lines competing for your business. Some applications are focused on the customer’s requirements for fleet and performance vehicles. Also, some replacement pads offer “better than OE” features that can reduce corrosion with better coatings and platings.

Post time: Jul-28-2021